Overview

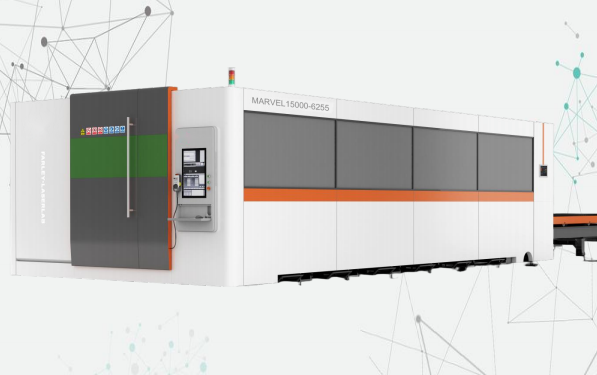

Integrating automation, informatization, intelligence and laser “intelligent” manufacturing,

we provide a full range of laser cutting equipment. Comprehensively layout laser intelligent equipment and provide overall solutions for the construction of automated production lines and smart factories.

Three-dimensional five-axis laser cutting

.Mainly for automobile, aerospace, engineering machinery, Marine, hardware, decoration, medical instrument, mould, household appliance, body machine material and other leading city customers;

.solve the problem of three dimensional cutting of various metal workpiece, its characteristics are high precision, fast, low cost and simple operation maintenance.

FEATURES

.Mainly for automobile, aerospace, engineering machinery, Marine, hardware, decoration, medical instrument, mould, household appliance, body machine material and other leading city customers;

.solve the problem of three dimensional cutting of various metal workpiece, its characteristics are high precision, fast, low cost and simple operation maintenance.

BENEFITS

. The stability adopts a gantry dual-drive structure, which ensures high stability and can guarantee long-term high-speed and high-precision stable cutting

. The Diversity SF series of processed Fu Mian comes in four sizes: 3mx1.5m, 4mx2m,4mx2.5m, and 6mx2m. If you need other Fu mian, customization is available. Meanwhile, the workbench can be selected as a rotary type, a translational type or a fixed worktable according to customer requirements

. The expandable SF series can not only complete the three-dimensional cutting of workpieces, but also be used for flat plate cutting. Meanwhile, it is very easy to switch the Welding interface module on this platform. Expand it into a laser welding platform to achieve multiple functions in one machine.

. The safety protection of the SF series machine tools complies with the CE international safety standards

.Compared with the robot-type three-dimensional cutting agent, this one is faster and more precise in terms of cost performance. Compared with traditional laser cutting machines for carbon dioxide, it has lower usage costs, simpler operation and more convenient maintenance

SPECIFICATIONS

| Model | SF3015E | SF4020 | SF4025 | SF6020 |

| X/Y/Z axis trave | 3000/1500/680mm | 4000/200/680mm | 4000/2500/680mm | 6000/2000/680mm |

| A axis trave | ±135° | ±135° | ±135° | ±135° |

| C axis trave | ±n×360° | ±n×360° | ±n×360° | ±n×360° |

| Maximum speed along the X/Y/Z axis | 60m/min | 100m/min | 100m/min | 80m/min |

| Maximum acceleration along the A/C axis | 3600°/s² | 3600°/s² | 3600°/s² | 3600°/s² |

| Maximum speed of the A/C axis | 540/s | 540°/s² | 540°/s² | 540°/s² |

| Maximum acceleration along the X/Y/Z axis | 0.5G | 1G | 1G | 0.8G |

| Positioning accuracy of X/Y/Z axes | ±0.05mm | ±0.05mm | ±0.05mm | ±0.05mm |

| Repeat positioning accuracy of X/Y/Z axes | ±0.03mm | ±0.03mm | ±0.03mm | ±0.03mm |

| A/C axis positioning accur | 0.03° | 0.03° | 0.03° | 0.03° |

| Repeat positioning accuracy of A/C axes | 0.01° | 0.01° | 0.01° | 0.01° |

| Floating aid shaft range | ±12.5mm | ±125mm | ±12.5mm | ±12.5mm |

| Numerical control system | SIEME NS 840D SL | SIEM ENS 840D SL | SIEM ENS 840D SL | SIEM ENS 840D SL |

| Configurable laser | 1000-6000W | 1000-6000W | 1000-6000W | 1000-6000W |